The Underhill Casting Solution System

is made with the highest quality material to give you years of use. They were created

from over a decade of resin casting experience and fine-tuned to suit your casting needs for the hobbyist

and commercial caster. How do we know this? … because they are the same casting supplies we have been using

during our many years of producing high quality blanks, that are sold on the market today, to pen turners across the world.

|

The Original Vertical Casting System

The design of this system allows you to make multiple blanks at the same time. No matter what type of casting you’re in to making,

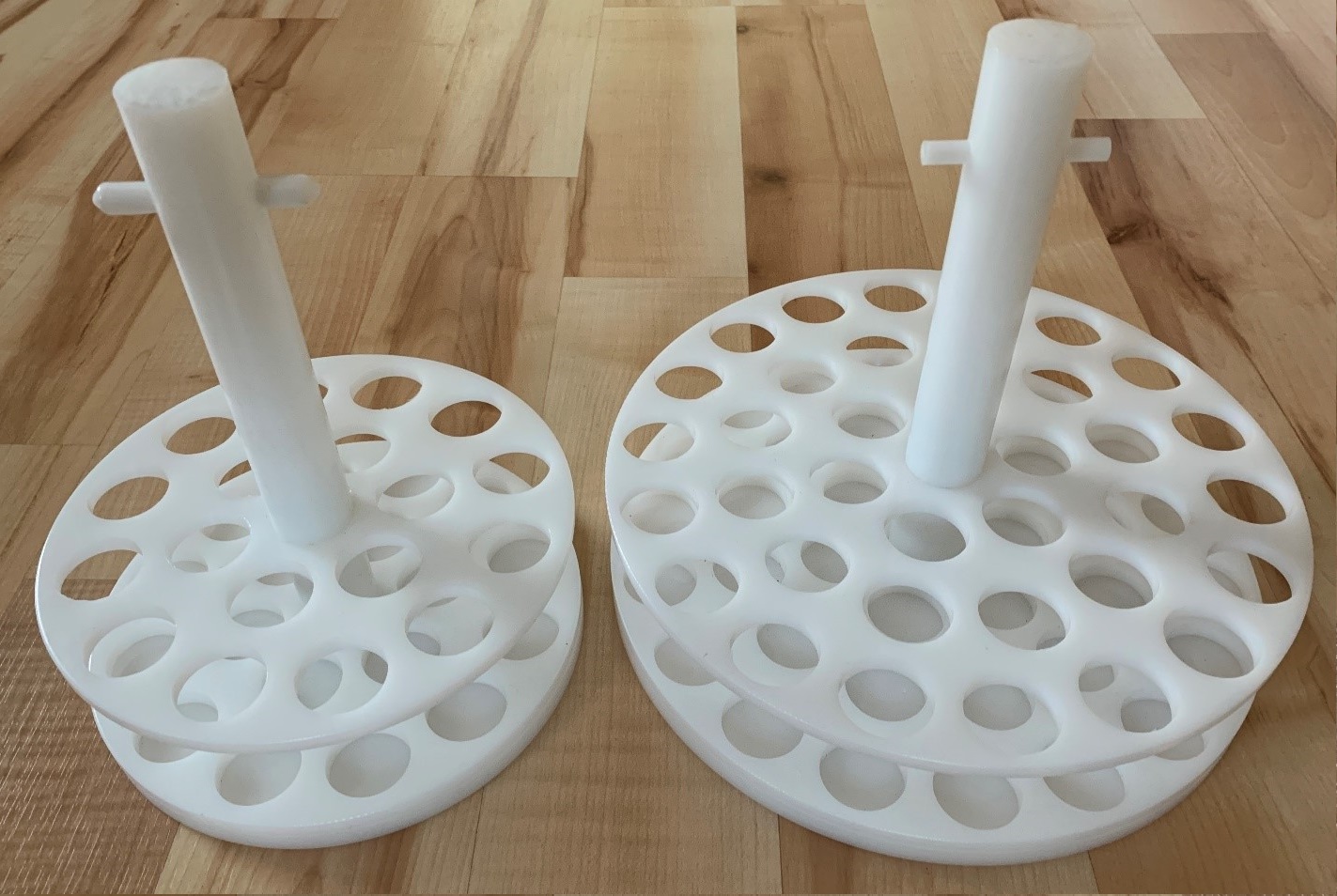

clear cast/ tube on, embedded objects or colored blanks, this system has you covered. It’s offered in two different sizes,

The Standard 18 (allowing you to cast 18 tubes at once) or The Double 36 (allowing you to cast up to 36 tubes at once).

|

This system uses clear tubes as the mold that you cut to the desired length, depending on the blank you’re making.

Tapered plugs are used for tube on casting to seal the brass tube and help hold it in place. A top coil holds the

brass tube upright allowing for quick pouring of the resin and easy escape for air. Two different reusable bases

are included for tube on casting or color and embedded object casting. All of these accessories come with the system

when purchased or can be purchased separately at Exoticblanks.com as needed.

The simple assembly of the mold tubes allows you to cast every sized brass pen tube on the market without the need of

purchasing a separate mold for each size, from the largest to the smallest brass tubes. The only thing that changes is

the size of the tapered plug. This system is designed to work with all resin types (Polyester, Urethane, Epoxy) used in

pen making today.

This system uses clear tubes as the mold that you cut to the desired length, depending on the blank you’re making.

The benefits of this system:

• Made of smooth HDPE for easy clean up

• Saves you time, maximizing your blank production in each pour (up to 36 tubes at one time)

• Saves you resin, eliminating corners that will be removed in turning

• Saves you money, not having to purchase a separate mold for each pen tube size

• Reduces the risk of blowouts while turning because the blank is cast round

• Allows air bubbles to rise and float away from the blank reducing the risk of failures

• Bases and Tapered plugs are all reusable

• The T-handle construction allows easy and quick placement in and out of the pressure pot

• Open tube top and Coil Wire allow for quick pour of resin maximizing your resin working time

The vertical casting system will come fully assembled with easy to follow videos on molding, using, and demolding your blanks. The bottom of the rack is made of

two pieces allowing for easy cleaning of spilled resin with a “one screw” disassembly. The spacer and handle are made to only fit one way for reassembly so there

is never a problem with the top and bottom rack holes lining up.

Click here to purchase The Vertical Casting System and Accessories!

|